Get free udemy courses on plc with udemy 100% coupon. Use udemy free

course coupon to get plc udemy paid courses for free without

downloading. No need to download udemy courses for free.

These are the

best online tutorials and courses to learn SPS step by step.

Collected by udemy with 100 coupons, these free PLC courses are offered

for free. Get free no-download udemy courses. Find the best PLC

tutorials with videos and get free training and hands-on PLC knowledge.

Start with SPS for free and learn quickly from scratch as a beginner.

Find free plc udemy courses for beginners that include projects,

hands-on exercises, quizzes and tests, video lectures, examples and can

improve your plc.

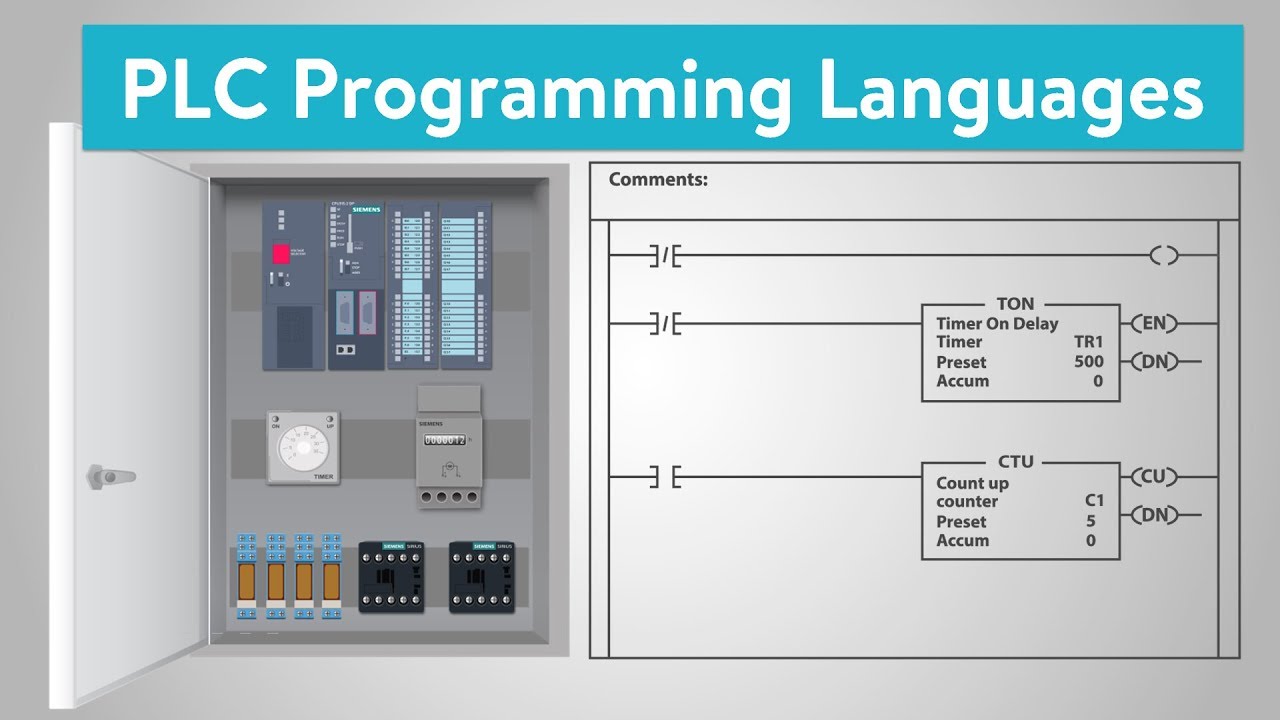

Programmable Logic Controllers (PLCs) are the major components in industrial automation and control systems. The controlling nature of PLC is ranging from simple- push button switching to a single motor to several complex control structures. The PLC programming is an important task of designing and implementing control application depending on customers need. A PLC program consists of a set of instructions either in textual or graphical form, which represents the logic to be implemented for specific industrial realtime applications.

A dedicated PLC programming software comes from a PLC hardware of specific manufacturer that allows entry and development of user application code, which can be finally download to the PLC hardware. This software also ensures Human Machine Interface (HMI) as a graphical representation of variables. Once this program gets downloaded to the PLC and if the PLC is placed in Run mode, then the PLC continuously works according to the program. Before going to the program of the PLC, let us know the basics of the PLC programming tutorial and its basic concepts.

PLC Programming Basics

A CPU of the PLC executes two different programs:

1. The Operating System

2. The User Program

The Operating System

The operating system organizes all the functions, operations and sequences of the CPU that are not associated with a control task. The OS tasks include

- Handling a hot restart and warm restart

- Updating and outputting the process image tables of input and outputs

- Executing the user program

- Detecting and calling the interrupts

- Managing the memory areas

- Establishing communication with programmable devices

The User Program

It is a combination of various functions which are required to process an automated task. This must be created by the users and need to be downloaded to the CPU of the PLC. Some of the tasks of the user program include:

Initiating all the conditions for starting the specified task

Reading and evaluating all binary and analog input signals

Specifying output signals to all binary and analog output signals

Executing interrupts and handling errors

In present industrial automation sector, there are several leading PLC manufactures that develop typical PLC’s ranging from small to high-end PLC’s. Each and every PLC manufacturer has its own dedicated software to program and configure the PLC hardware. But the PLC programming language is varied depending on the manufacturers. Some manufacturers have common programming languages and some others have dissimilar. Some of the standard programming languages of PLC are basically of two types, which are further sub-divided into several types, which are as follows:

1.Textual language

Instructions List (IL)

Structured Text (ST)

2. Graphical language

Ladder Diagrams (LD)

Function Block Diagram (FBD)

Sequential Function Chart (SFC)

THE WHAT?

The heart of every control systems is a PLC or Programmable Logic Controller. The PLC is behind most products and industries.

1. The water in your tap, behind it is a water treatment process which involves Control Systems.

2. The electricity in your households came from power plants. The power generation process involves Control Systems.

3. The fuel that is running our cars and industries. The oil exploration, extraction and refinery processes involves Control Systems.

4. The multi-vitamins and medicine that you get from the pharmacies or hospitals. Manufacturing it is a very stringent process which involves Control Systems.

THE WHY?

If you are an engineer or an engineering student. Learning how to program a PLC is an important skill set that will take you to a very rewarding career.

THE HOW?

In this course, we will be teaching you how to program a PLC in a universal approach, that you can even perform your PLC logic development on paper.

We will be using Function Block Diagram PLC programming language, because it is used by most of the big industries like Oil & Gas, Water Treatment, Power Generation, Petrochemical and Pharmaceutical.