Factory I/O is a 3D PLC (Programmable Logic Controller) simulator that provides a platform for developing, testing and debugging control systems in a virtual environment. It allows users to create and simulate real-world industrial processes, including automation, robotics, and mechatronics systems.

The software offers a comprehensive library of 3D models and components, including sensors, actuators, PLCs, and other industrial devices, which can be used to build and test control systems. The built-in PLC editor supports multiple PLC programming languages, including Ladder Logic, Structured Text, and Function Block Diagram, making it suitable for a wide range of applications.

Factory I/O also supports real-time communication with physical PLCs and other industrial devices, allowing users to test and debug control systems before deploying them in the real world. This can save time and reduce the risk of errors and downtime in production environments.

The software provides an intuitive, interactive 3D environment, which makes it easy to visualize and understand the behavior of industrial processes. This can be especially useful for training and education purposes, allowing students and engineers to gain practical experience with control systems without the need for expensive equipment and hardware.

Benefits of Factory I/O :

There are several benefits to using Factory I/O as a 3D PLC simulator:

1. Cost Savings: By testing and debugging control systems in a virtual environment, users can avoid the cost and risk associated with making changes in real production environments.

2. Improved Efficiency: Factory I/O allows users to develop and test control systems in a fraction of the time it would take to build and test physical prototypes.

3. Increased Safety: Testing control systems in a virtual environment eliminates the risk of damage to equipment and personnel, which can be especially important in hazardous environments.

4. Improved Understanding: The 3D visualization of industrial processes provided by Factory I/O makes it easier for users to understand the behavior of complex control systems and identify potential issues before they arise.

5. Accessibility: Factory I/O is designed to be user-friendly and accessible, making it suitable for use by engineers, students, and educators alike.

6. Flexibility: The software supports multiple PLC programming languages and communication protocols, making it suitable for a wide range of applications.

7. Integration: Factory I/O can be integrated with real PLCs and other industrial devices, allowing users to test and debug control systems in a real-world environment.

Overall, Factory I/O provides a powerful, flexible, and cost-effective solution for developing, testing, and debugging control systems in a virtual environment.

Features of Factory I/O 3D PLC Simulator

Here are some of the key features of Factory I/O 3D PLC Simulator:

- 3D Simulation Environment: Factory I/O provides an intuitive and interactive 3D environment for simulating industrial processes and testing control systems.

- PLC Programming: The built-in PLC editor supports multiple programming languages, including Ladder Logic, Structured Text, and Function Block Diagram.

- Real-Time Communication: Factory I/O supports real-time communication with physical PLCs and other industrial devices, allowing users to test control systems in a real-world environment.

- 3D Model Library: The software includes a comprehensive library of 3D models and components, including sensors, actuators, PLCs, and other industrial devices.

- Alarm Management: Factory I/O provides tools for configuring and managing alarms, including visual and auditory notifications, email and SMS notifications, and more.

- Historical Trending: The software supports historical trending, allowing users to view and analyze process data over time.

- Multi-Language Support: Factory I/O supports multiple languages, making it suitable for use in global operations.

- Easy Configuration: The software provides a range of tools for design and configuration, including object libraries, wizards, and drag-and-drop functionality.

- Integration: Factory I/O can be integrated with other industrial software and devices, allowing users to create end-to-end solutions.

- User-Friendly Interface: Factory I/O is designed to be user-friendly, with a clear and intuitive interface that makes it easy to use for engineers and students alike.

Factory I/O 3D PLC Simulator Technical Setup Details

Here are the technical details for setting up Factory I/O 3D PLC Simulator:

1. System Requirements: Factory I/O requires a Windows-based operating system and a graphics card that supports DirectX 11.0. The minimum system requirements are:

• Windows 7,8,10.

• Dual-core processor

• 4 GB of RAM

• DirectX 11.0 compatible graphics card

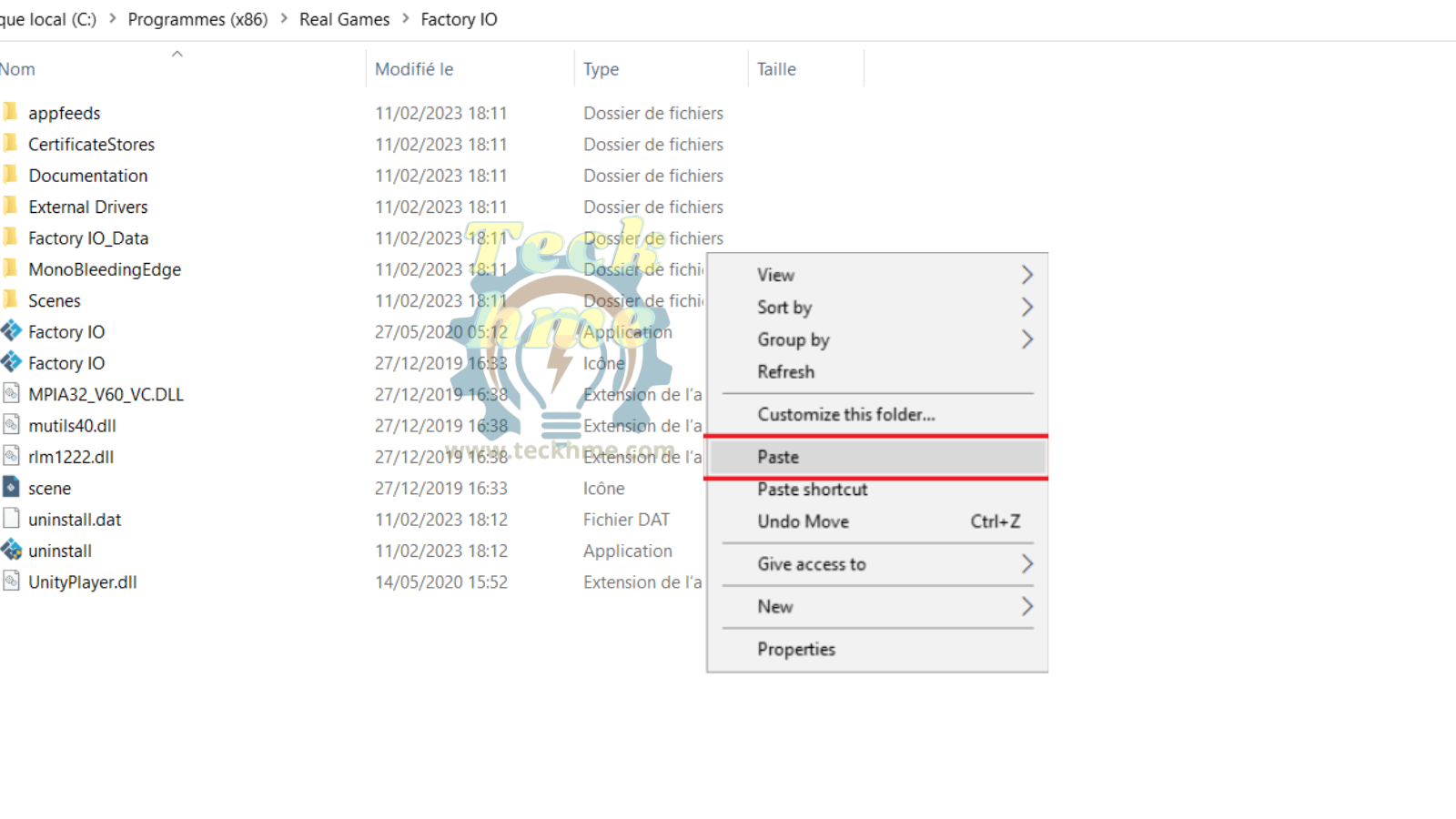

2. Installation: Factory I/O can be installed by downloading the setup file from the official website and following the installation instructions. The installation process will install the software, its dependencies, and the necessary drivers.

3. License Activation: Factory I/O requires a license to be activated before it can be used. The license can be purchased from the official website or from an authorized reseller.

4. User Manual: Factory I/O comes with a comprehensive user manual that provides detailed instructions for using the software, including how to set up and configure control systems, how to use the PLC editor, and how to use the 3D simulation environment.

5. Technical Support: Factory I/O provides technical support to users through its official website, including a FAQ section, a knowledge base, and a forum. In addition, users can contact the support team for assistance with specific issues.

6. Updating: Factory I/O can be updated to the latest version by downloading and installing the updated software from the official website. Updates may include new features, bug fixes, and performance improvements.

system requirements for Factory I/O 3D PLC Simulator are as follows:

1.Operating System: Windows 7, 8, 8.1, 10 (64-bit)

2.Processor: Intel Core i3 or equivalent

3.Memory: 4 GB RAM

4.Graphics: NVIDIA GeForce GTX 760 or equivalent

5.DirectX: Version 11

6.Storage: 2 GB available space